What is material requirements planning?

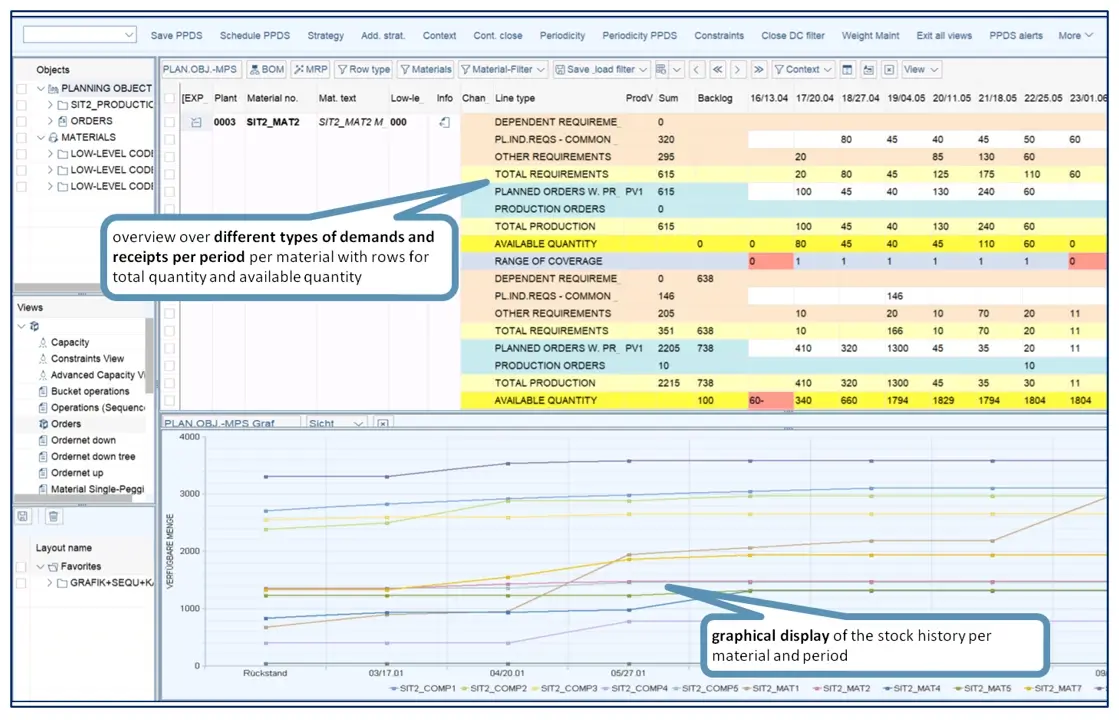

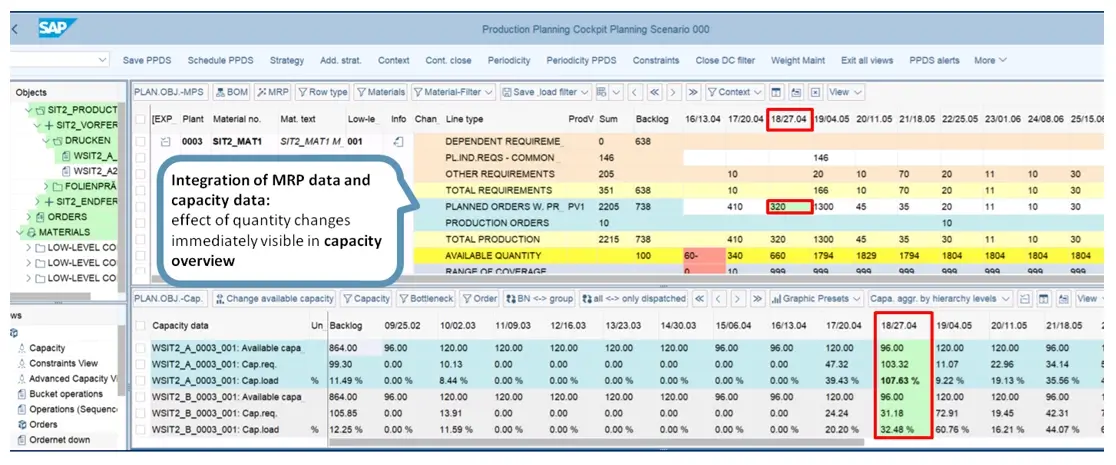

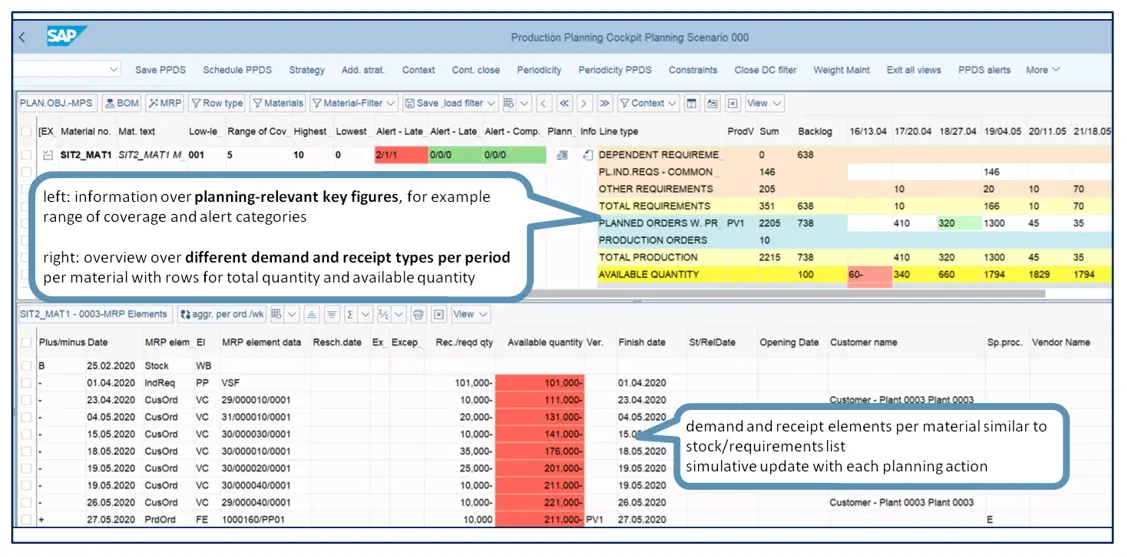

Within the context of material requirements planning, the responsible MRP controller ensures that the materials for which he is responsible are available on time at every point in the supply chain.

The following must be provided in good time:

- Raw materials

- Assembled items

- Finished products

- Subcontracted components

- Stock transfers between plants

This means that material requirements planning is a constant matching of requirements and receipts - similar to the interaction of assets and liabilities or incoming and outgoing on an account.