SAP SCM planning features

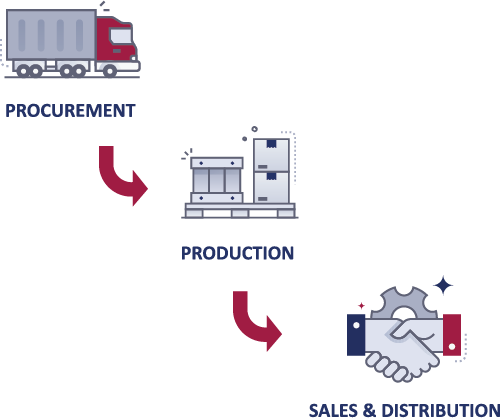

The supply chain covers all steps, from purchasing, manufacturing, production and assembly of components to delivery to the customer. Special cases such as subcontracting, production in different plants, stock transfers and WIP (Work in Process) are also taken into account.

SAP Supply Chain Management software (SCM) maps the entire supply chain in the system and provides helpful and supporting features for all areas.

SCM Planning focuses on the planning aspect when considering supply chains. Although planning refers to the future, it must of course always take into account the current situation in the supply chain such as stocks, confirmations, WIP, actual production times and so on.

Specifically, an SCM planning tool combines data from procurement to manufacturing to delivery as well as possible service/maintenance across all levels of the supply chain.

Pegging is a decisive factor here, as it creates links between the various levels of the supply chain - even outside a sales order scenario (make-to-order, MTO), in make-to-stock production (MTS). Combinations of both scenarios (MTO, MTS) are also possible and supported.