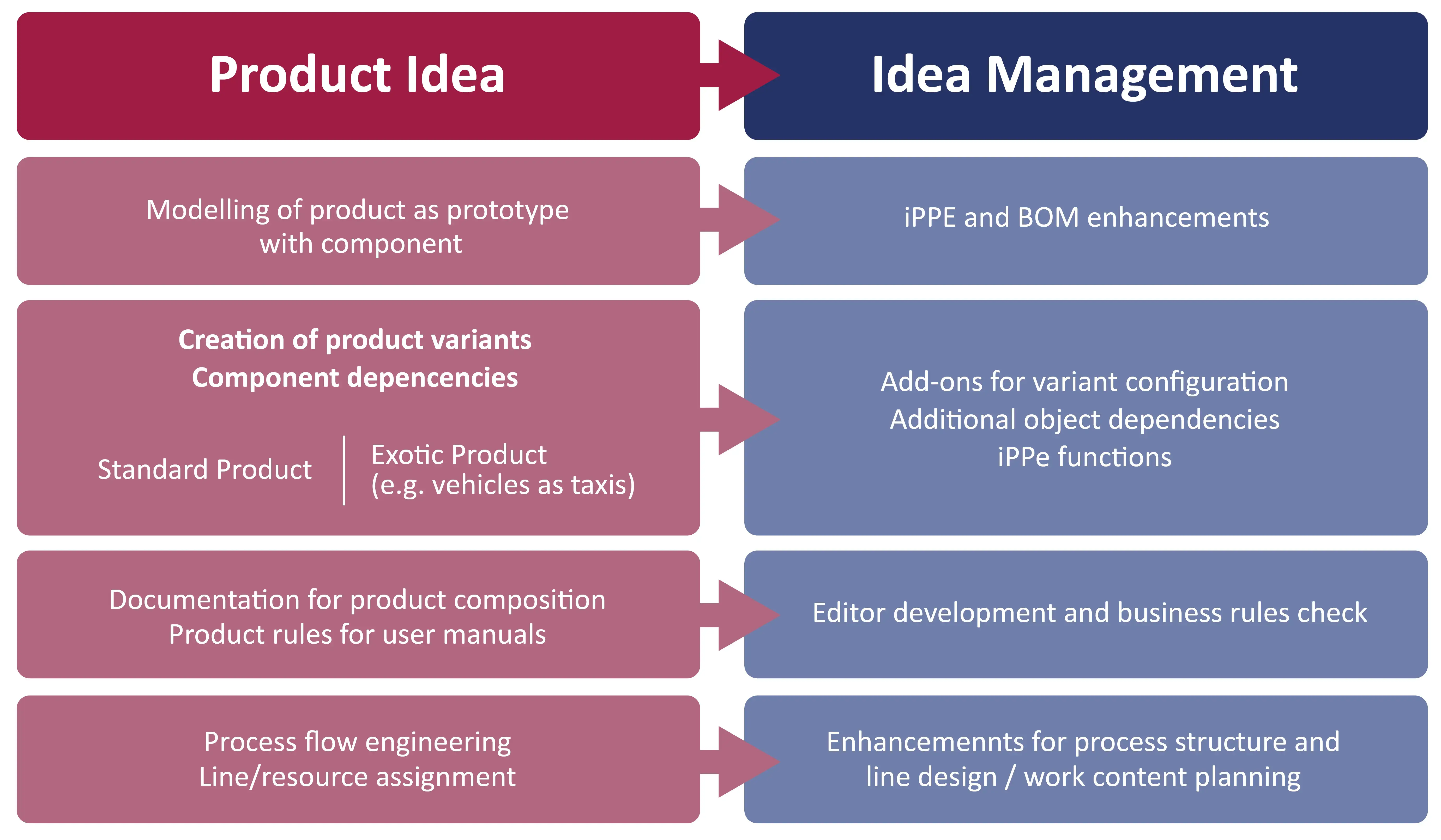

The Integrated Product and Process Engineering (iPPE) component of SAP is a comprehensive tool designed to consolidate all pertinent data across the entire lifecycle of highly variant products into an unified model. During the initial stages of product development, iPPE facilitates the documentation of data, which can then be utilized and refined throughout the subsequent phases. Its capability to maintain master data across Bill of Materials (BOM), routings, and line design within a singular model enables the creation of a detailed production process blueprint. This feature renders SAP iPPE exceptionally advantageous for industries engaged in repetitive manufacturing, where efficiency and consistency are paramount.

Furthermore, SAP iPPE allows for the initial maintenance of data within a functional structure, which is then progressively enriched with additional information as the product development advances. This progressive data enrichment is critical for visualizing the complete lifecycle of the product. A standout feature of the iPPE framework is its interface that facilitates integration with time analysis tools. This integration is crucial for determining accurate processing times, which are then seamlessly incorporated into the iPPE model. By offering a bridge to time analysis applications, iPPE enhances the precision of production planning and process engineering, making it an invaluable asset for optimizing manufacturing operations and reducing time-to-market for products with complex variants and specifications.