PPC ATP Planner for the availability check

PPC ATP Planner for the availability check

It is of paramount importance for the production process to ensure that sufficient production capacity and all necessary components are always available. Therefore, the availability check also plays a significant role in business software systems that offer functionalities for in-house production and external procurement planning.

The PPC ATP Planner is fully integrated into the SAP standard and is based on the ATP logic of the SAP availability check. The integrated option of capacity analysis and the consideration of multi-level dynamic order networks create a substantial added value for your supply chain planning. The transparent display of the capacity load on your resources and multi-level material availability in the same user interface makes it easier to get quick reliable statements about delivery dates. Allowing you to identify problems in the supply chain early, track their causes and simulate possible solutions.

Functional interaction of analysis and planning

Analysis of the existing situation: Availability check of materials and capacity

The multi-level analysis of the demand and receipt situation indicates whether the observed demands (e.g. from sales orders) can be covered completely and in time. It also indicates whether the receipt elements find sufficient free capacity on the resources.

-

Dynamic creation of multi-level order networks

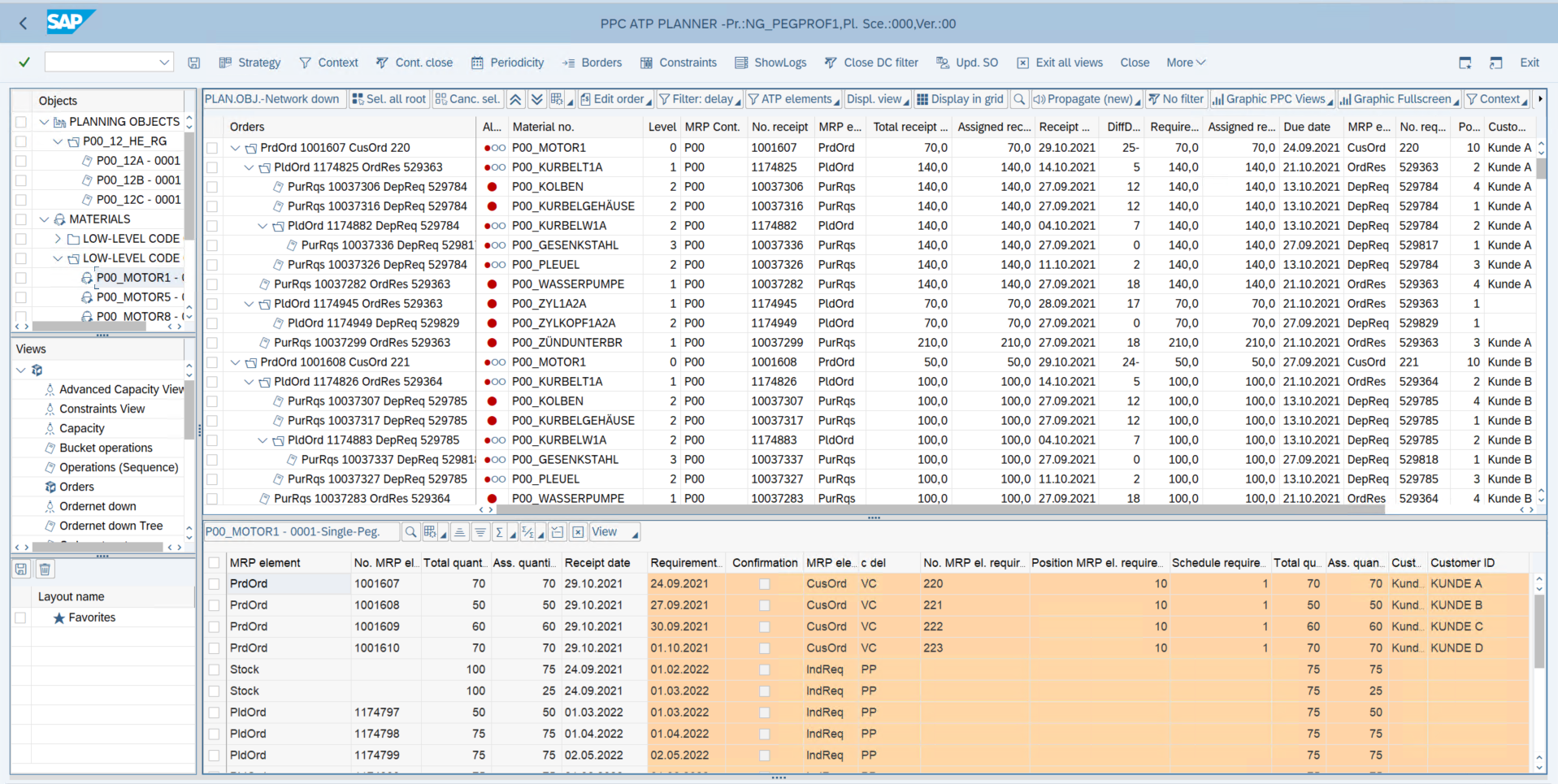

Across all production levels demand and receipt elements are dynamically linked (in a so-called “pegging structure”; assigning receipts to demands is called “pegging”). Significant key figures allow the planner, even in anonymous make-to-stock production, to quickly identify at which points in the production process problems are likely to arise.

Multi-level order network with pegging according to ATP logic for a material

-

Prioritisation of certain demands

Flexible settings permit the prioritisation of different demand elements, e.g., to cover specific customer demands first. The prioritisation can be inherited to subordinate production levels.

-

Pegged requirements display

The multi-level upwards analysis starts from demands or receipts on a lower production level and determines which independent demands on the top level are covered by them. Example: The planner would like to find out what consequences a shortness of supplies has and which sales orders are affected by this.

- Availability check

Based on demands or receipts on a higher production level, the multi-level downwards analysis determines if the material availability is guaranteed on all subordinate production levels. Example: The planner checks whether all components are available on time to release a production order or to deliver a sales order by the deadline.

-

Consideration of capacity bottlenecks

In order to be able to determine a realistic customer delivery date it is essential to identify and fix overloads early. For this purpose, the capacity load of relevant resources in the analysed order network is displayed.

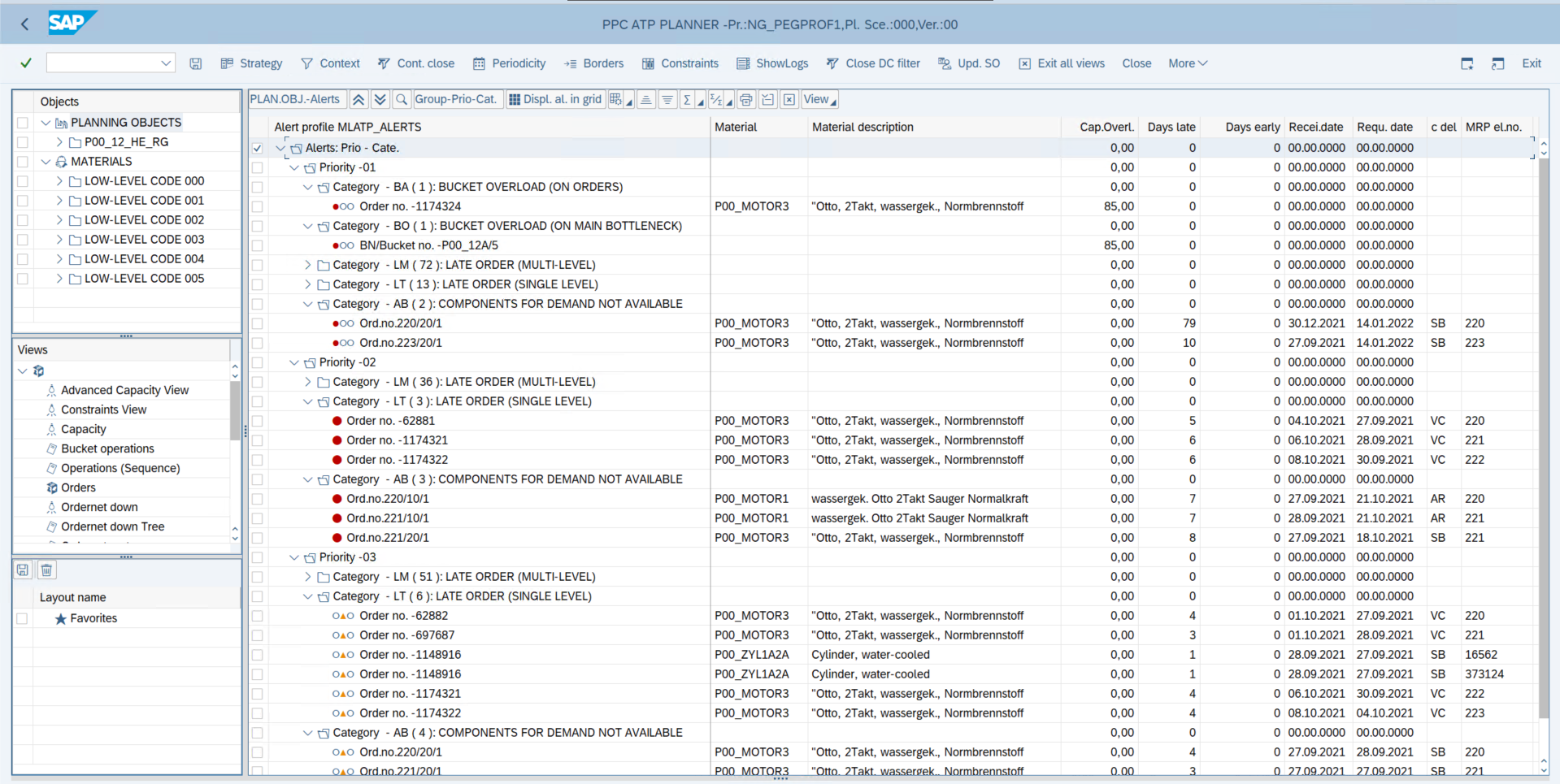

- Flexible settings for alerts

Customisable alerts help the planner identify critical issues quickly. For example, alerts can be set for delayed receipts, lack of raw materials, or missing pegged requirements (multi-level), as well as capacity overloads.

- Cross-plant scenarios

The analysis is not limited to one plant. Order networks can be created across several plants. The result is an overview of the entire supply chain.

-

Transparent and clear overview

The results of the analysis are shown in a user interface with different views, between which you can navigate comfortably. Using various filters and layouts, the user individually adjusts the display to his needs, so that he can find important information immediately. Links to numerous relevant SAP standard transactions complete the cockpit of the PPC ATP Planner.

-

Seamless integration into SAP

No new interfaces need to be implemented nor any additional hardware needs to be purchased to use the PPC ATP Planner. It works directly with SAP objects so that no master data must be created twice. After saving, all changes are immediately and consistently effective in SAP.

Planning: Assurance of material and capacity availability

Based on the results of the availability check, steps to assure availability can be undertaken: Generate new MRP-relevant receipts in case of material shortage or postpone existing receipts due to resource overloads or missing components.

-

Automatic adjustment of order networks

Scheduling inconsistencies in multi-level order networks are resolved automatically by intelligent algorithms. For example, the order network can be adapted to the late arrival of a purchase order to place planned and production orders on manageable dates, to which the components are available.

- Multi-level capacity levelling with re-scheduling of the order network

In addition to scheduling inconsistencies, capacity overloads in the order network can be eliminated automatically. This enables the creation of a feasible multi-level production plan checked against available capacity (also referred to as “CTP”). Various planning logics from the PPC-Sequencer for detailed planning or from the PPC-Rough-Cut-Planner for rough planning can be used.

Order network with automatic adjustment

- Simulation of new MRP-relevant receipts

If material shortages in the order network are detected during the material availability check, new MRP receipt elements can be generated by simulation. Therefore, analysis can be continued for subordinated components. When saving, simulated receipt elements can be automatically created in SAP on request.

- Simulation of new demands and demand changes

In order to evaluate what-if scenarios, additional demands or demand changes are simulated and the resulting effects on the material and capacity situation are observed instantly. Likewise, an analysis of SAP long-term planning scenarios is possible.

-

Determination of feasible realistic delivery dates

A simultaneous multi-level check of material and capacity availability determines the feasibility and thus reliable delivery dates for customer demands, so that high delivery reliability is achieved.

-

Update sales order

Determined delivery dates are taken directly from the availability check and taken as confirmed dates in the sales orders.

-

Sales order integration

The PPC ATP Planner can also be called instead of the SAP standard availability check directly from a sales order (VA01/VA02) or a scheduling agreement (VA31/VA32) – without any modifications. The result of the analysis can be transferred directly to the sales order.

All in all, the functions of the PPC ATP Planner ensure that the planning accuracy in your company improves significantly and that you can meet the delivery dates promised to your customers.