PPC Sequencer

Die Grundlage für eine effiziente und transparente Fertigung ist ein detaillierter, realisierbarer Produktionsplan.

Die Grundlage für eine effiziente und transparente Fertigung ist ein detaillierter, realisierbarer Produktionsplan.

In der Feinplanung, die normalerweise im Kurzfristhorizont zum Einsatz kommt, sind die relevanten Zielgrößen folgende:

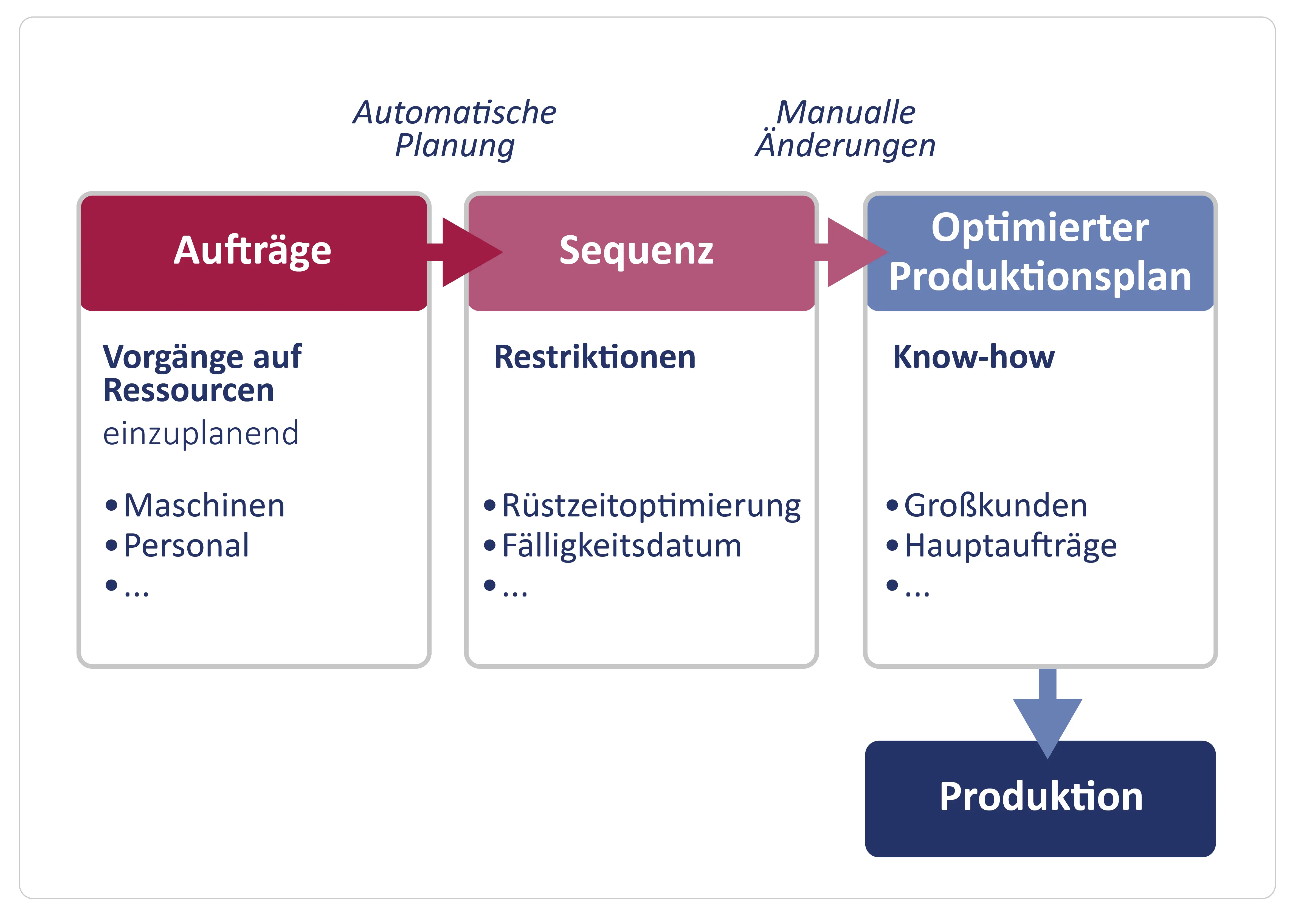

Die Feinplanung (Sequenzplanung) umfasst vor allem die Aspekte der optimalen, zeitkontinuierlichen Reihenfolgebildung von Vorgängen/Aufträgen und des detaillierten Abgleichs von Produktionskapazitäten innerhalb eines kurzfristigen Horizonts.

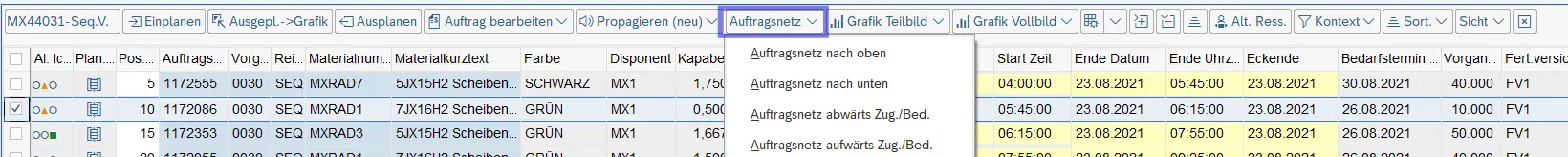

Multi-level order network with pegging according to ATP logic for a material

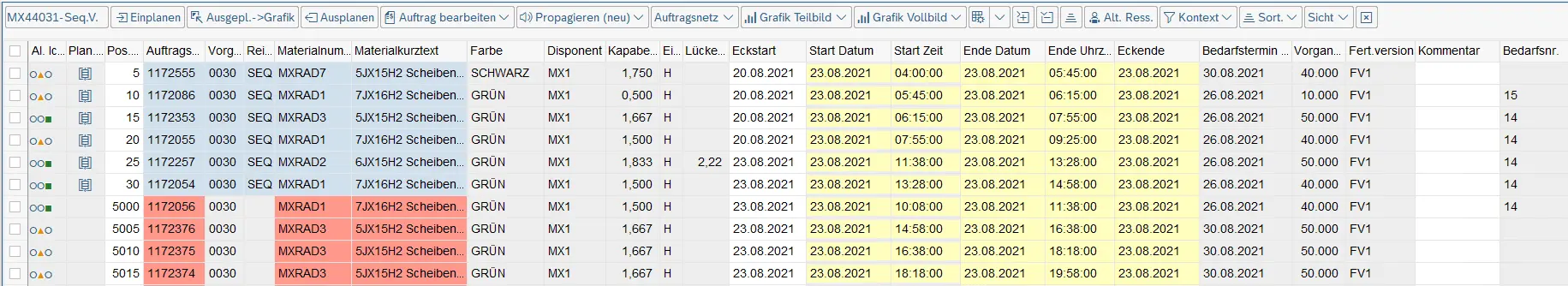

Feinplanungsübersicht: Terminierung/Sequenzierung von Fertigungs- und Planaufträgen mit dazugehörigen Detailinfos, z. B. Soll-/Bedarfstermin, Produktmerkmale (hier Farbe), Materialbeschreibung, Dauer, und Menge.

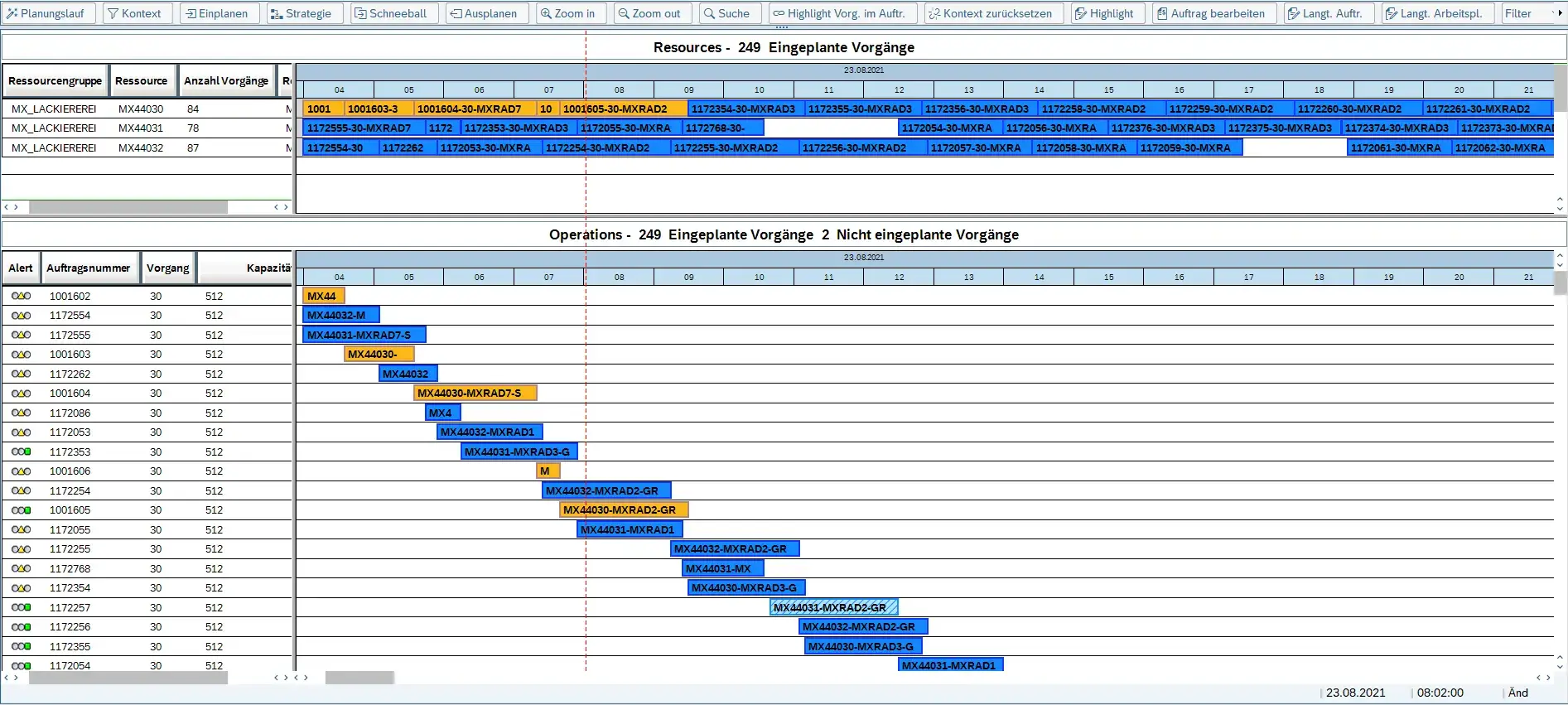

Feinplanungsübersicht: grafische Plantafel

Die Feinplanung kann komplett im Hintergrund durchgeführt werden oder im Dialog über den entsprechenden Funktionscode im PPC Sequencer.

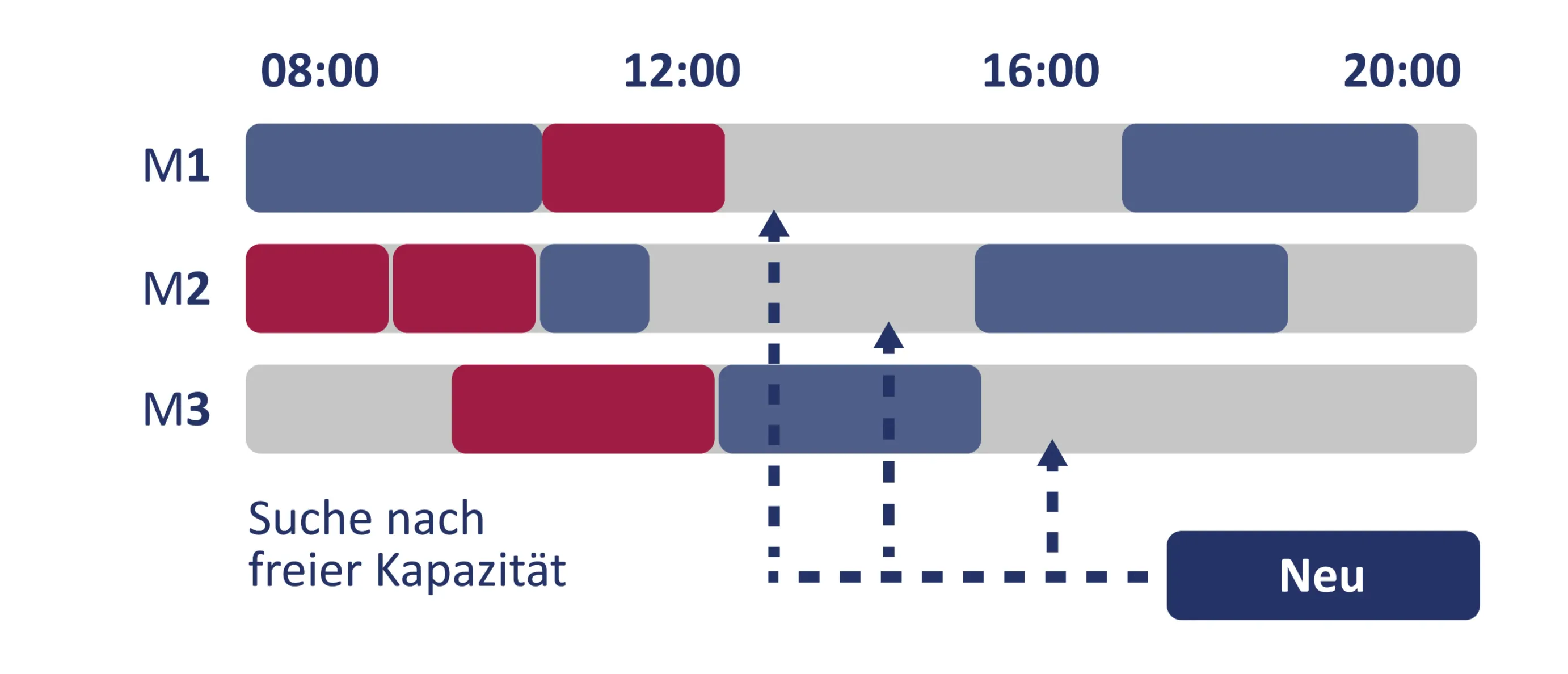

Eine manuelle Planung ist auch möglich, wobei dem Verantwortlichen viele Hilfsmittel zu einer optimalen Umsetzung seiner Entscheidungen zur Verfügung stehen:

Ein wesentlicher Vorteil des PPC Sequencer ist die Kombination aus automatischer und manueller Feinplanung. Hierbei ermittelt der Planer über die automatische Einplanung eine Vorschlagsbelegung mit allen Konsequenzen (abgeleitete Kennzahlen, Ausnahmen), um diese anschließend manuell zu bearbeiten.

Ablauf einer semi-automatischen Feinplanung:

Absprung zu über-/untergeordneten Produktionsstufen zur Anzeige der Komponenten bzw. der verursachenden Bedarfe (z. B. Kundenaufträge)

Holen Sie sich unser einsatzbereites Produktionsplanungs-Cockpit und die dazugehörigen Module, um neue Möglichkeiten in Ihrer Produktionsplanung zu erschließen.

MehrLink to take you to the above page where you can learn more.Wir kennen den SAP-Standard in- und auswendig und können Ihnen helfen, das Beste für Ihre individuellen Bedürfnisse herauszuholen!

MehrLink to take you to the above page where you can learn more.Mit unserer Erfahrung können wir Ihr SAP-Fundament auf ein höheres Niveau bringen und Ihre Geschäftsprozesse mit individuellen Lösungen verbessern.

MehrLink to take you to the above page where you can learn more.